The manufacturer’s curtain walling, windows and doors all feature at Bayscape.

The full range of architectural glazing systems from Kawneer were specified for a stunning residential development at Cardiff marina because they are tried and tested products.

The Kawneer systems were selected for Phase One of Bayscape Ltd’s £40 million mixed-use development, which has itself been shortlisted for an award, by award-winning Rio architects who have used Kawneer systems on numerous residential and commercial projects over the years.

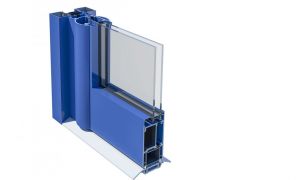

Kawneer’s AA®100 mullion-drained curtain walling with 50mm sightlines, thermally superior AA®720 tilturn and side-hung casement windows, and AA®545 open-out swing doors have been used throughout the two blocks of luxury apartments - Whitewater House and Waterford House – at Bayscape.

Whitewater House, so named because it also overlooks Cardiff International White Water Centre, was first to complete, offering 56 generously-proportioned one, two and three-bedroom apartments including two penthouses.

But Bayscape offers a total of 115 apartments, with optional private moorings, across seven and eight-storeys of apartments which are joined by an elevated garden podium. The ground floors feature a coffee shop, waterside bar and restaurant, commercial/retail units and marina management facility.

The luxury apartments, which all feature private balconies or terraces, start at £175,000 and range from up to 624ft2 for a one-bed, 990ft2 for two bedrooms and 1,119ft2 for a typical three-bedroom.

Residents benefit from under-croft parking, a concierge service and lift access to all floors. The impressive floor to ceiling double glazing in every apartment ensures they are light and airy and residents can enjoy the stunning views.

Rio director Andrew Baker said: “The brief was for a high-quality and distinctive development and we met that with a bold, well-mannered design.

“We specified Kawneer because of the need for a high-quality and trusted product. Crisp detailing was important in the overall design concept and aluminium was essential for the marine environment.”

The Kawneer systems were installed over five months by a team of up to eight operatives from approved dealer Dudley’s Aluminium for main contractor BECT Building Contractors. Dudley’s, which celebrates its 25th anniversary this year, also worked with Kawneer and BECT on another Cardiff project – One Canal Parade.

Bayscape was shortlisted for residential development of the year in the 2018 Wales Insider Property Awards.

The full range of architectural glazing systems from Kawneer were specified for a stunning residential development at Cardiff marina because they are tried and tested products.

The Kawneer systems were selected for Phase One of Bayscape Ltd’s £40 million mixed-use development, which has itself been shortlisted for an award, by award-winning Rio architects who have used Kawneer systems on numerous residential and commercial projects over the years.

Kawneer’s AA®100 mullion-drained curtain walling with 50mm sightlines, thermally superior AA®720 tilturn and side-hung casement windows, and AA®545 open-out swing doors have been used throughout the two blocks of luxury apartments - Whitewater House and Waterford House – at Bayscape.

Whitewater House, so named because it also overlooks Cardiff International White Water Centre, was first to complete, offering 56 generously-proportioned one, two and three-bedroom apartments including two penthouses.

But Bayscape offers a total of 115 apartments, with optional private moorings, across seven and eight-storeys of apartments which are joined by an elevated garden podium. The ground floors feature a coffee shop, waterside bar and restaurant, commercial/retail units and marina management facility.

The luxury apartments, which all feature private balconies or terraces, start at £175,000 and range from up to 624ft2 for a one-bed, 990ft2 for two bedrooms and 1,119ft2 for a typical three-bedroom.

Residents benefit from under-croft parking, a concierge service and lift access to all floors. The impressive floor to ceiling double glazing in every apartment ensures they are light and airy and residents can enjoy the stunning views.

Rio director Andrew Baker said: “The brief was for a high-quality and distinctive development and we met that with a bold, well-mannered design.

“We specified Kawneer because of the need for a high-quality and trusted product. Crisp detailing was important in the overall design concept and aluminium was essential for the marine environment.”

The Kawneer systems were installed over five months by a team of up to eight operatives from approved dealer Dudley’s Aluminium for main contractor BECT Building Contractors. Dudley’s, which celebrates its 25th anniversary this year, also worked with Kawneer and BECT on another Cardiff project – One Canal Parade.

Bayscape was shortlisted for residential development of the year in the 2018 Wales Insider Property Awards.